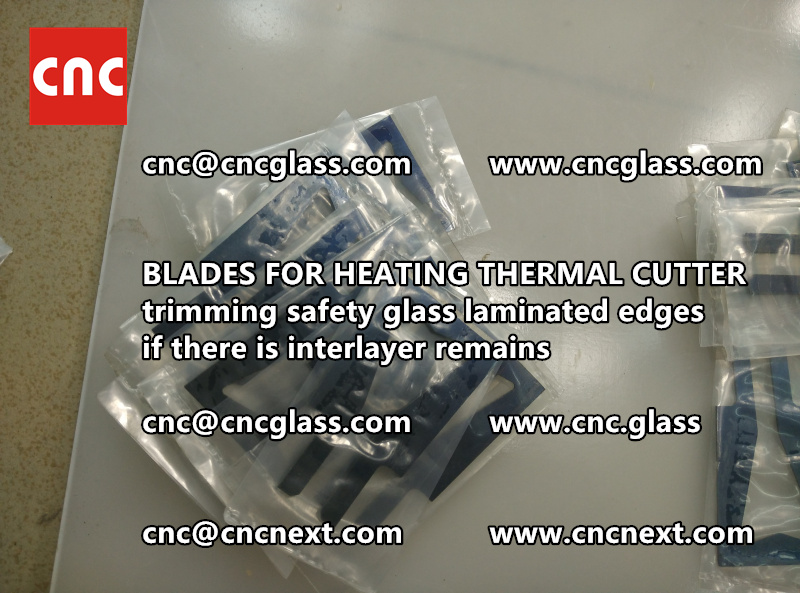

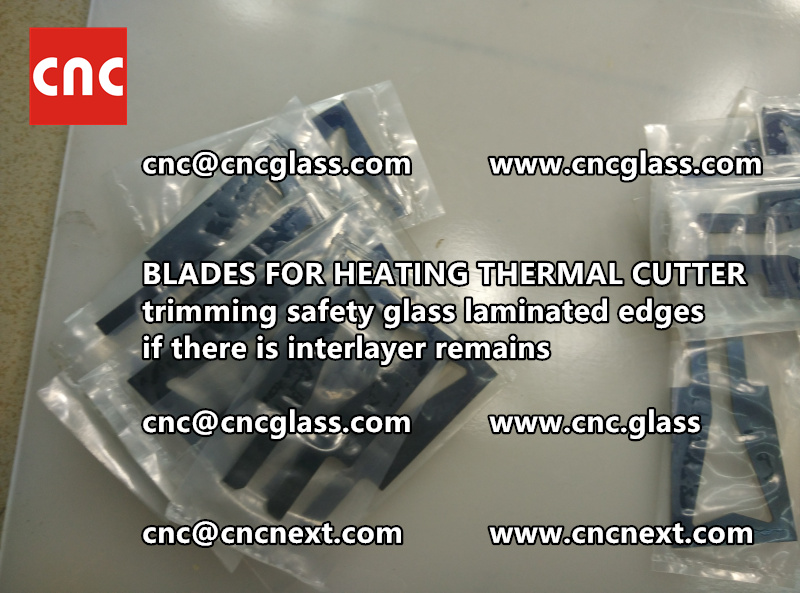

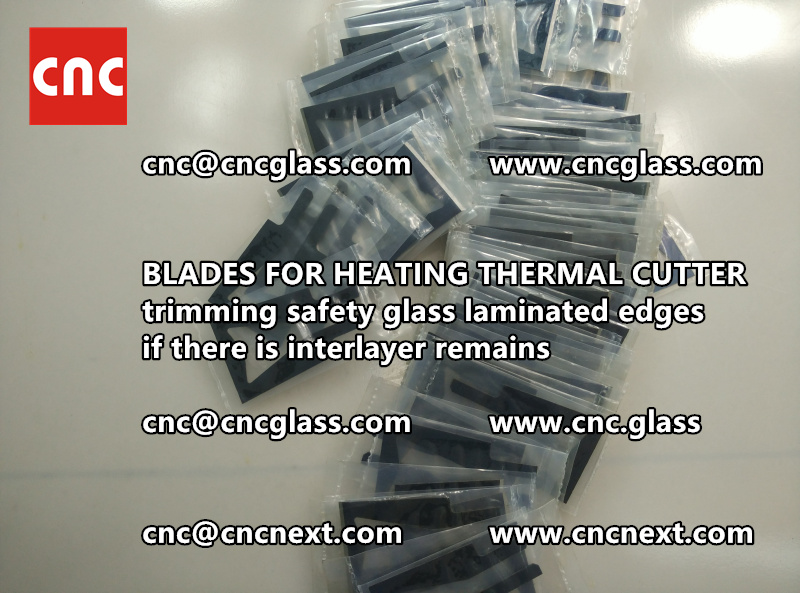

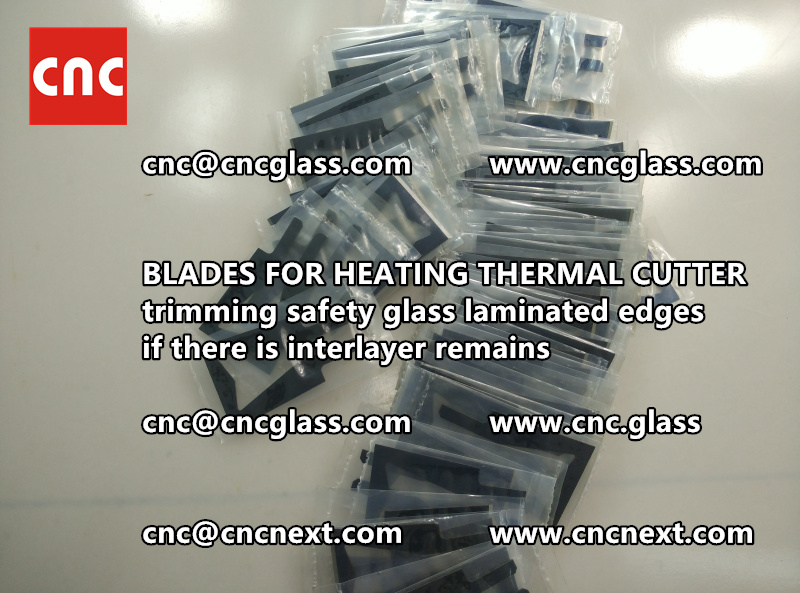

HOT KNIFE BLADES for trimming interlayer remains of laminated glass

THERMAL CUTTER BLADES for trimming interlayer remains of laminated glass

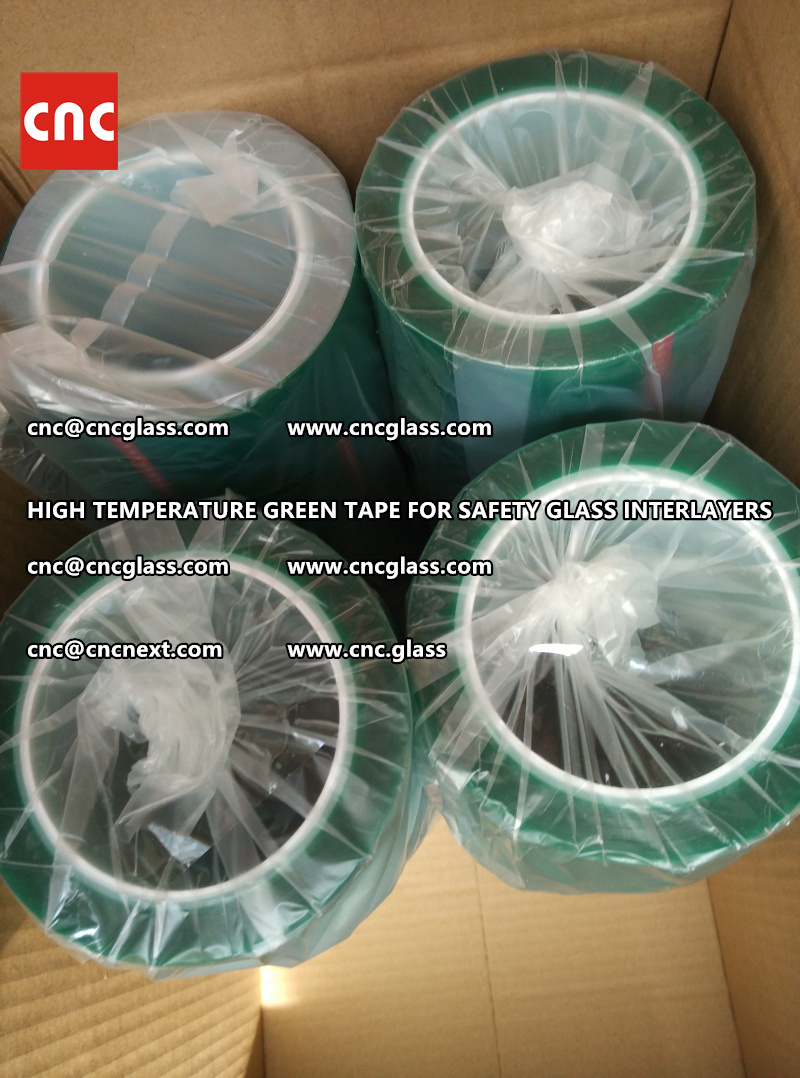

HIGH TEMPERATURE TAPE for safety glass lamination

SAFETY GLAZING PET GREEN TAPE (4)

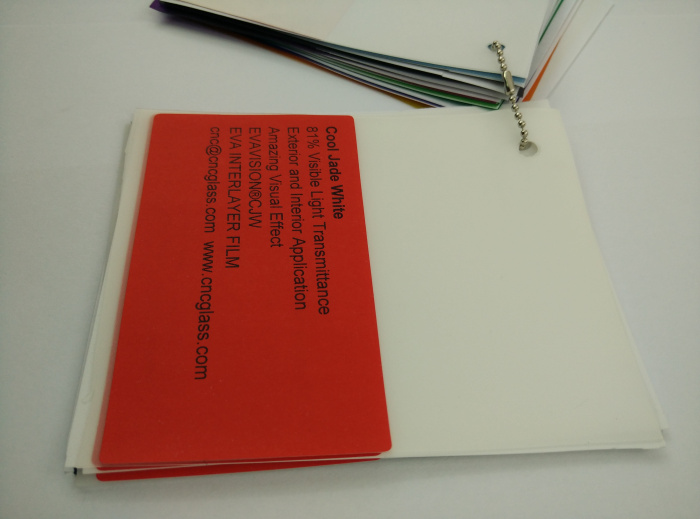

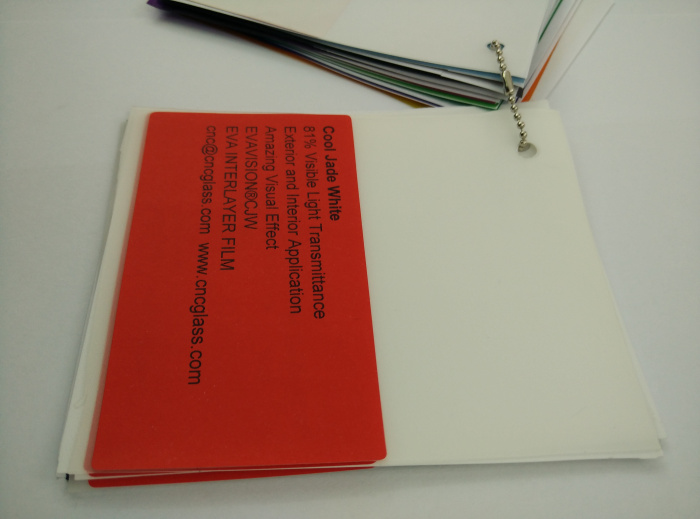

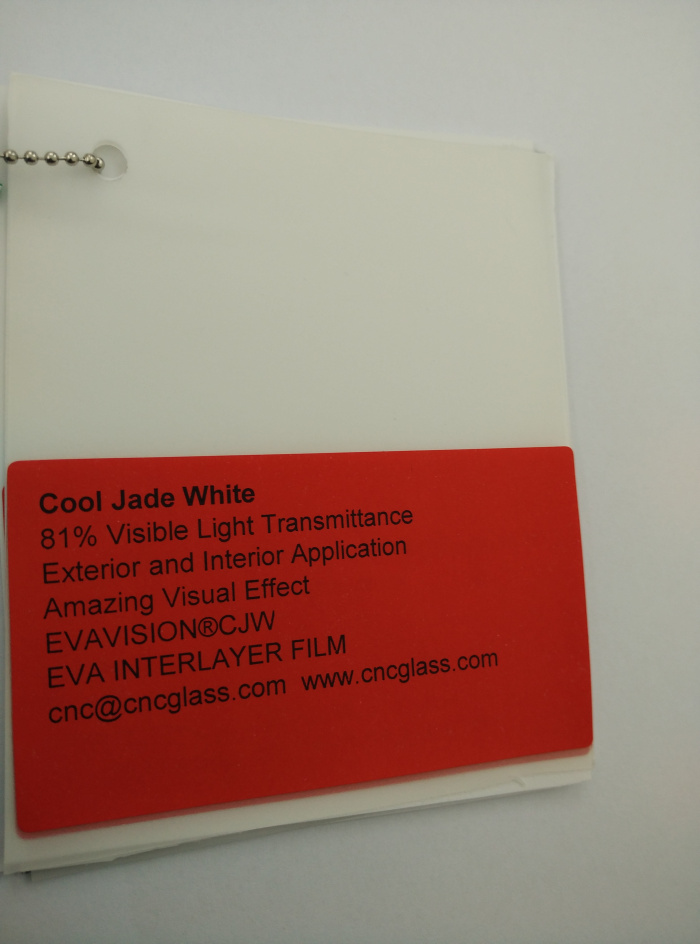

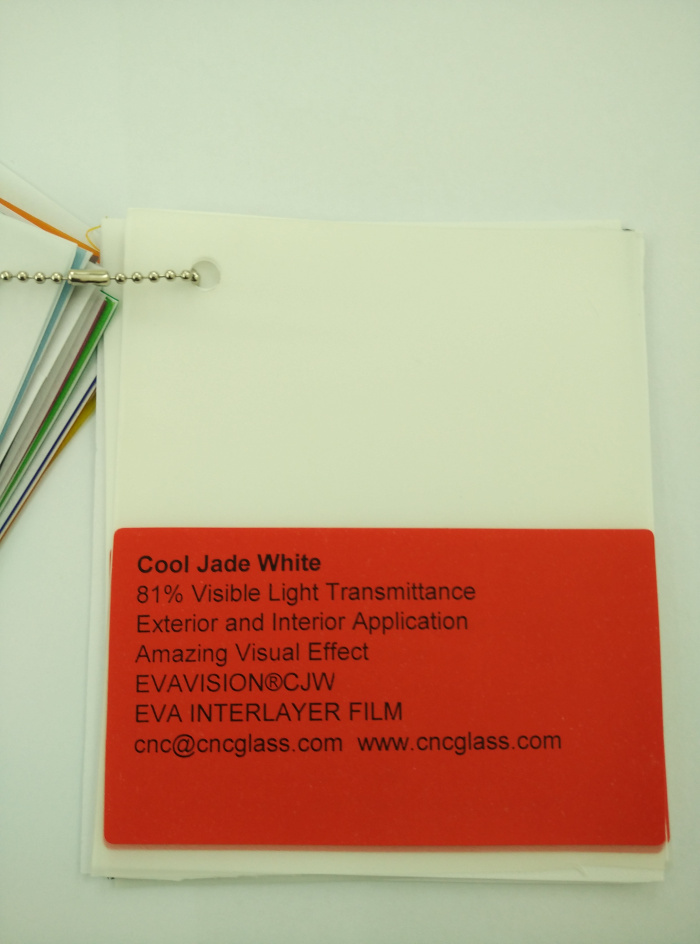

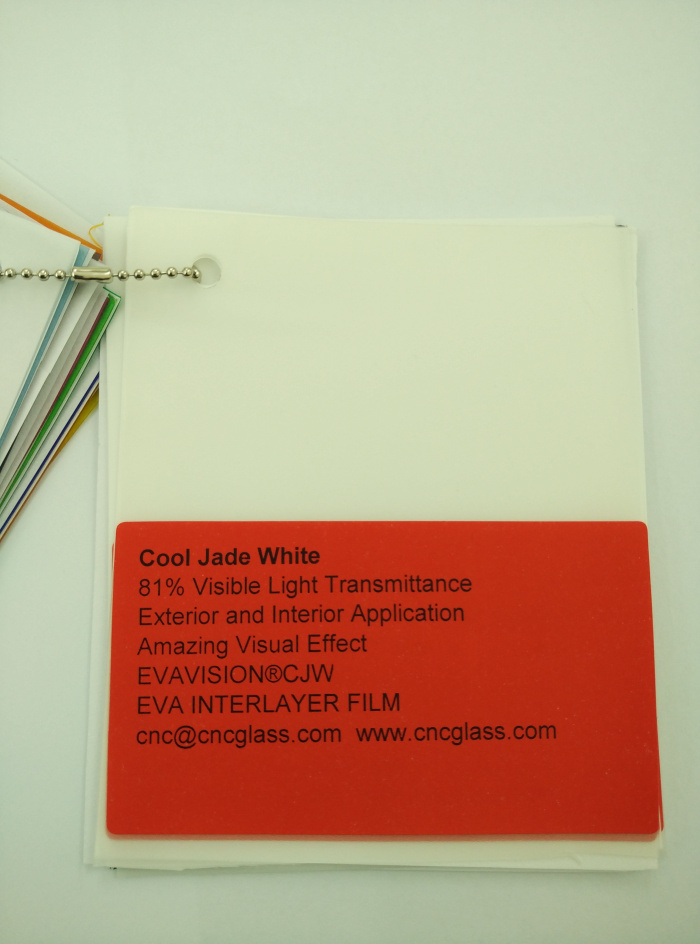

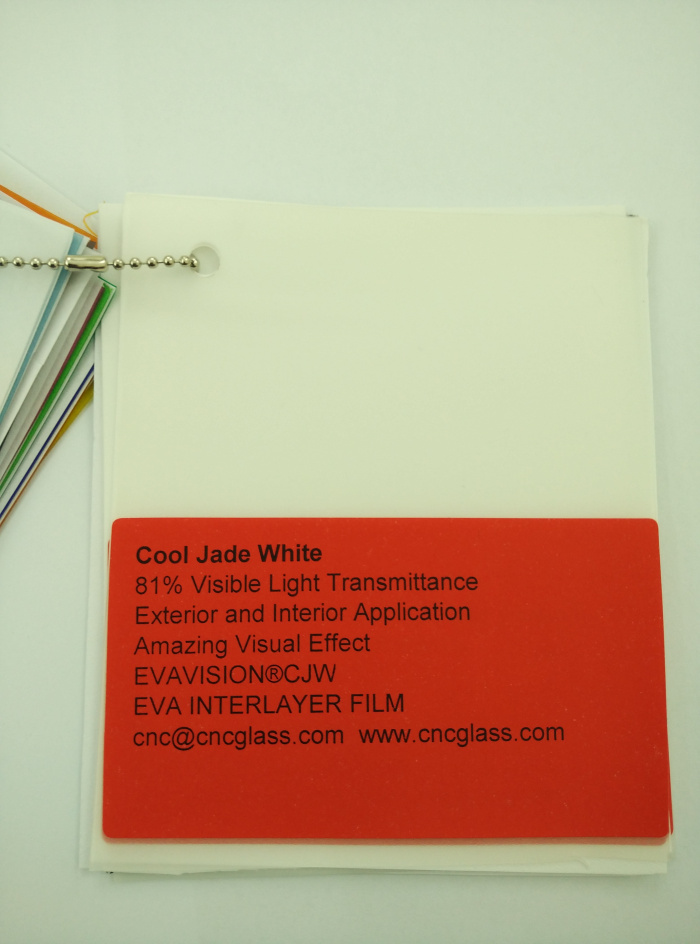

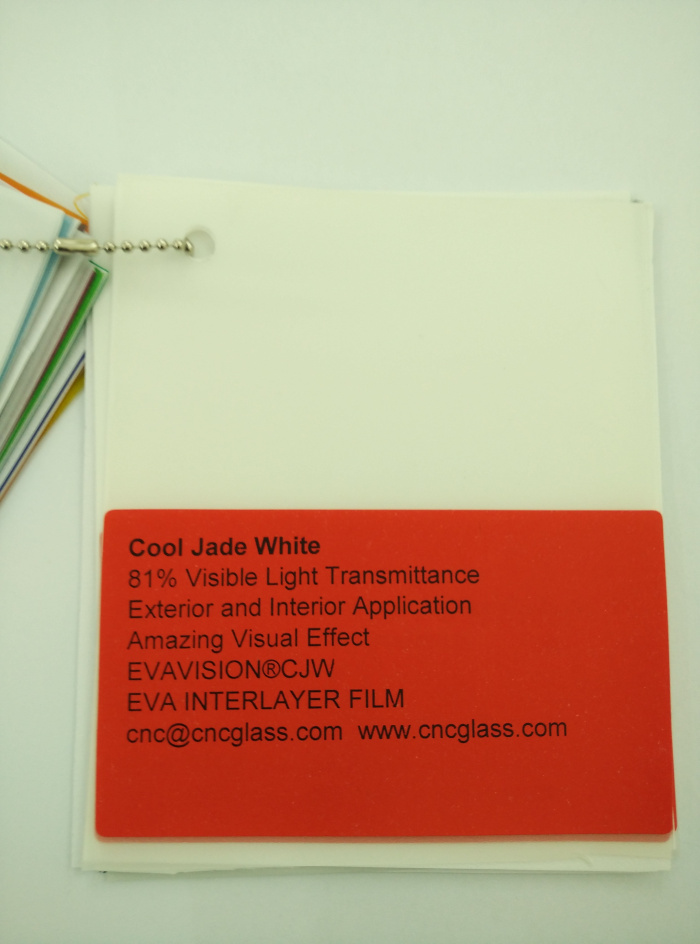

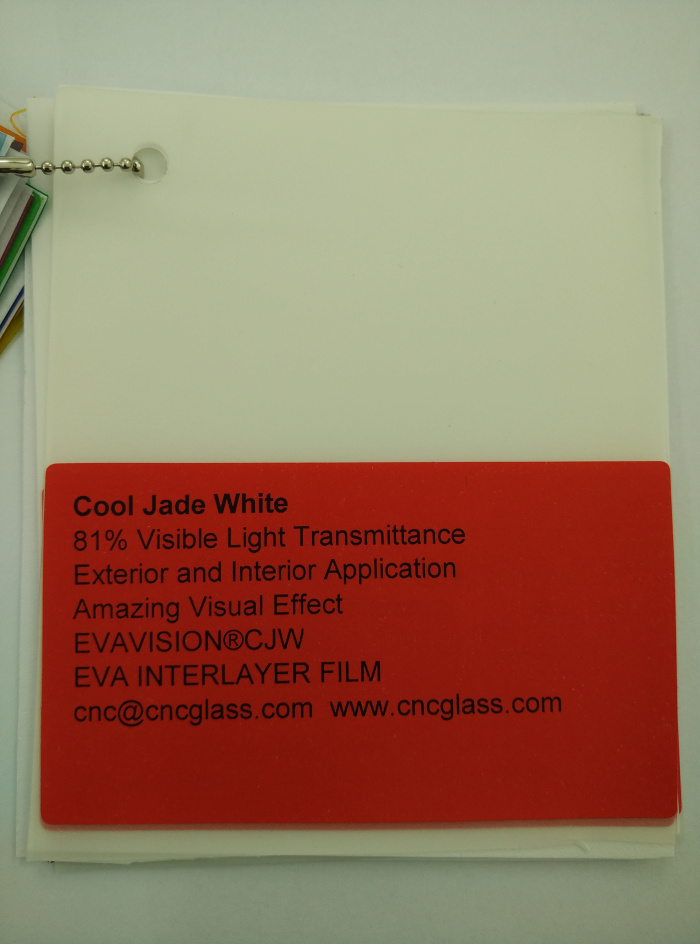

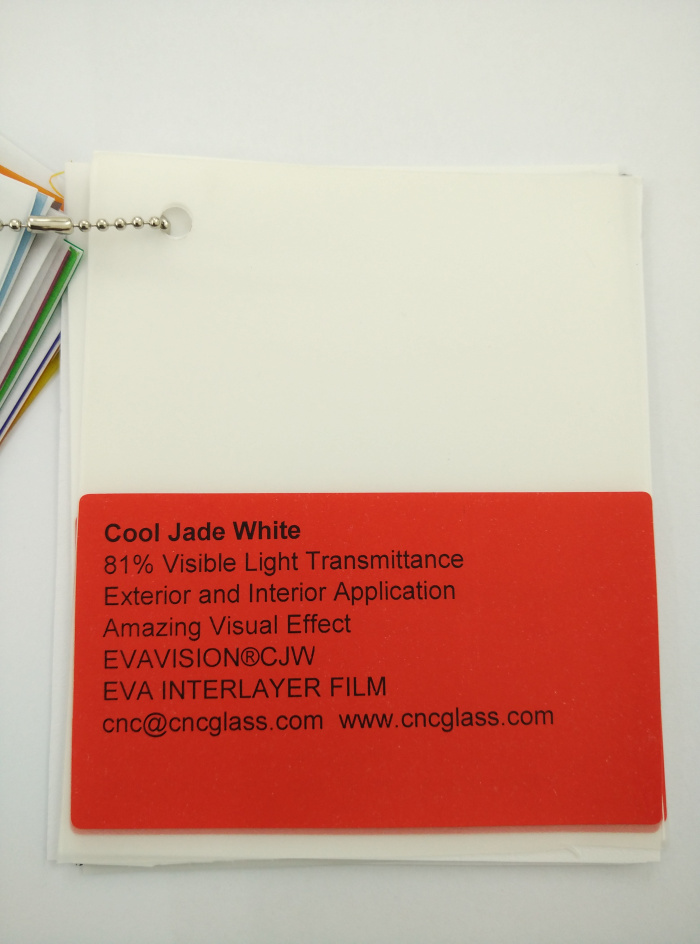

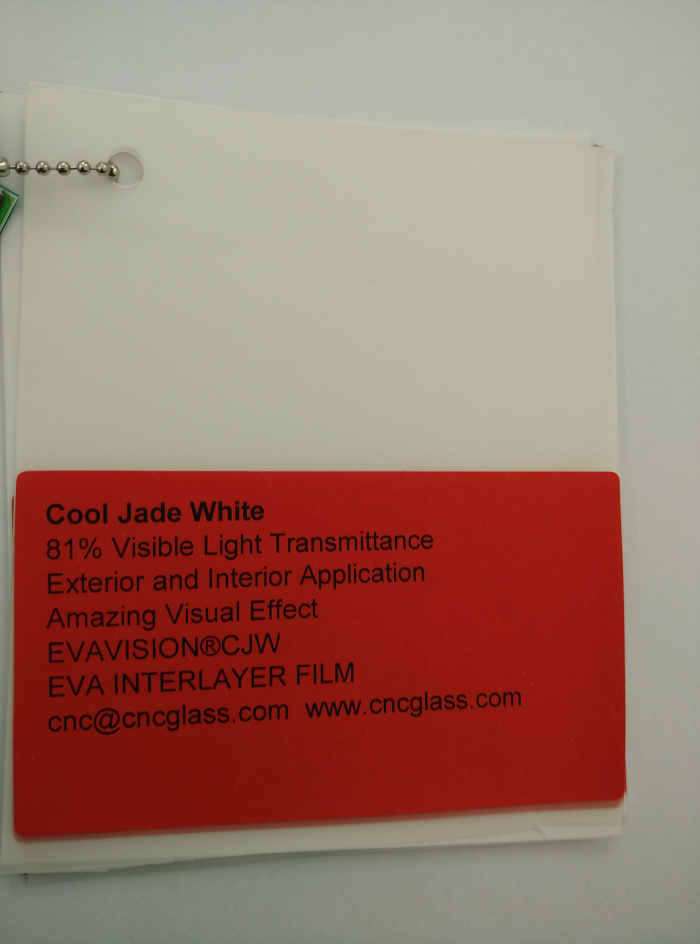

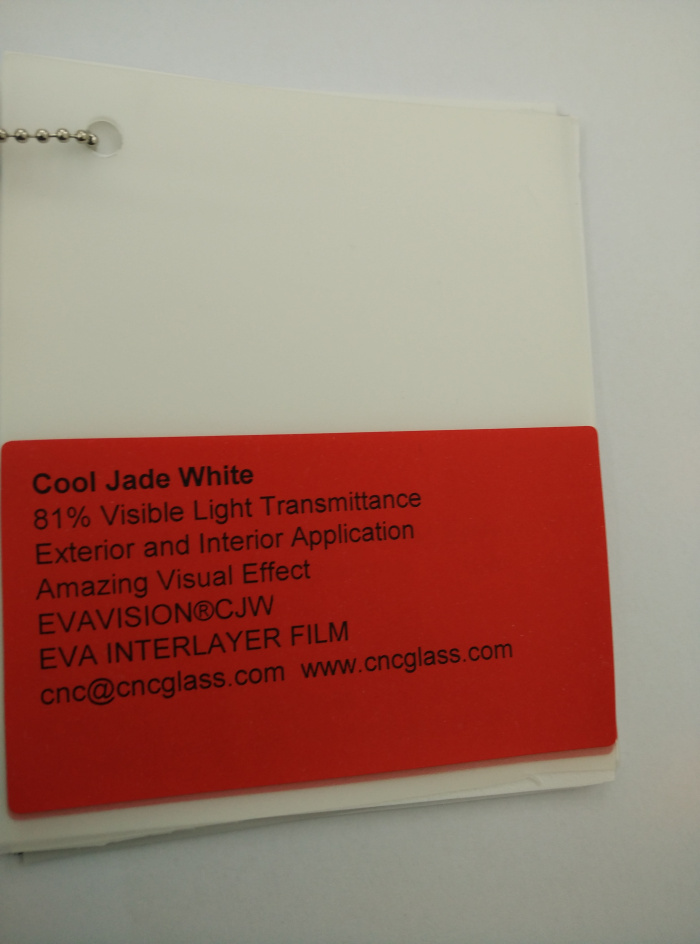

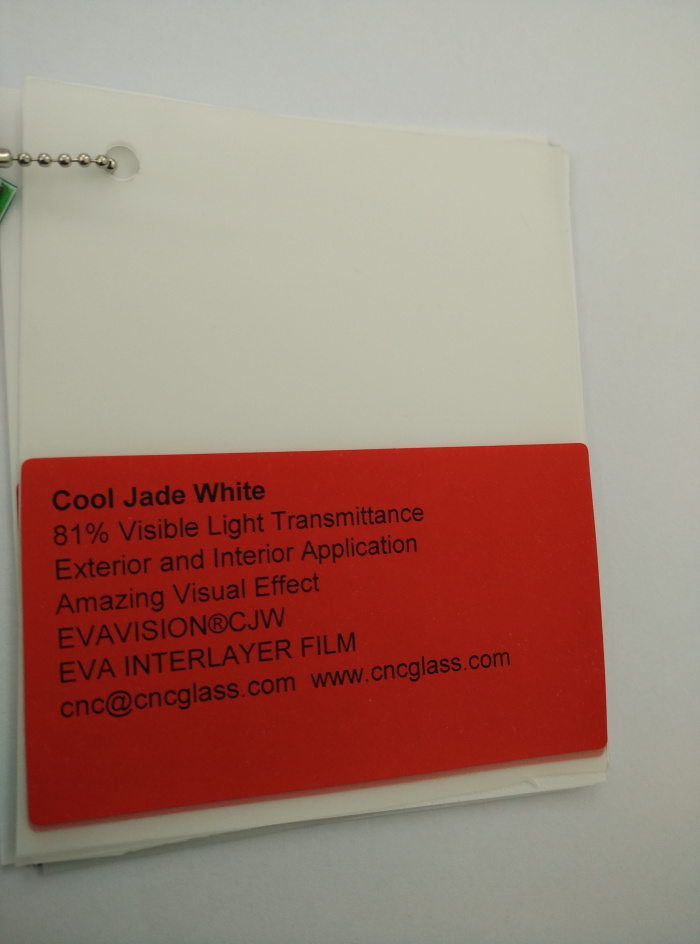

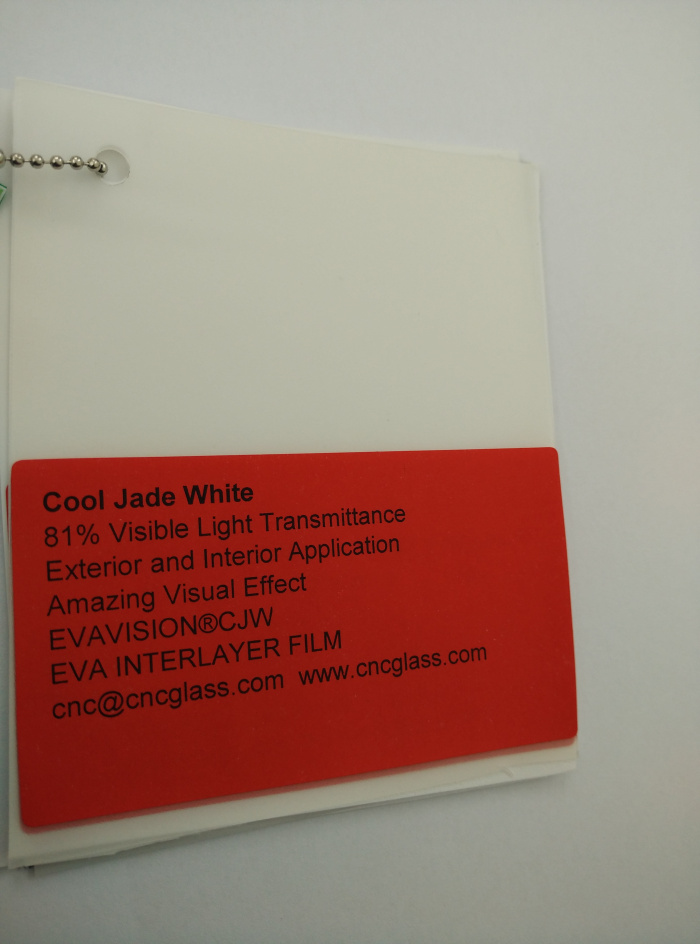

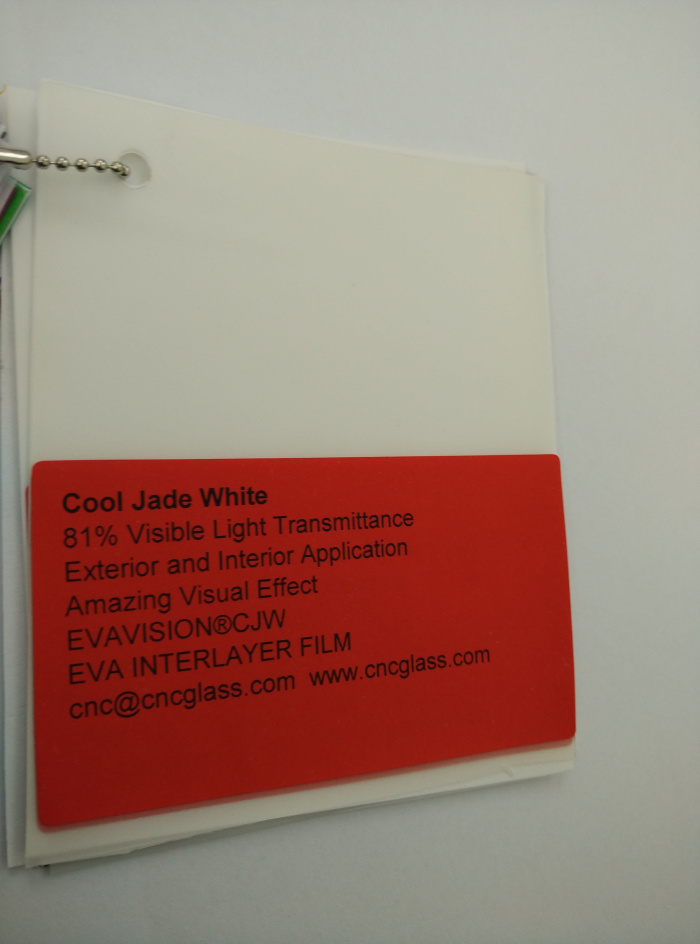

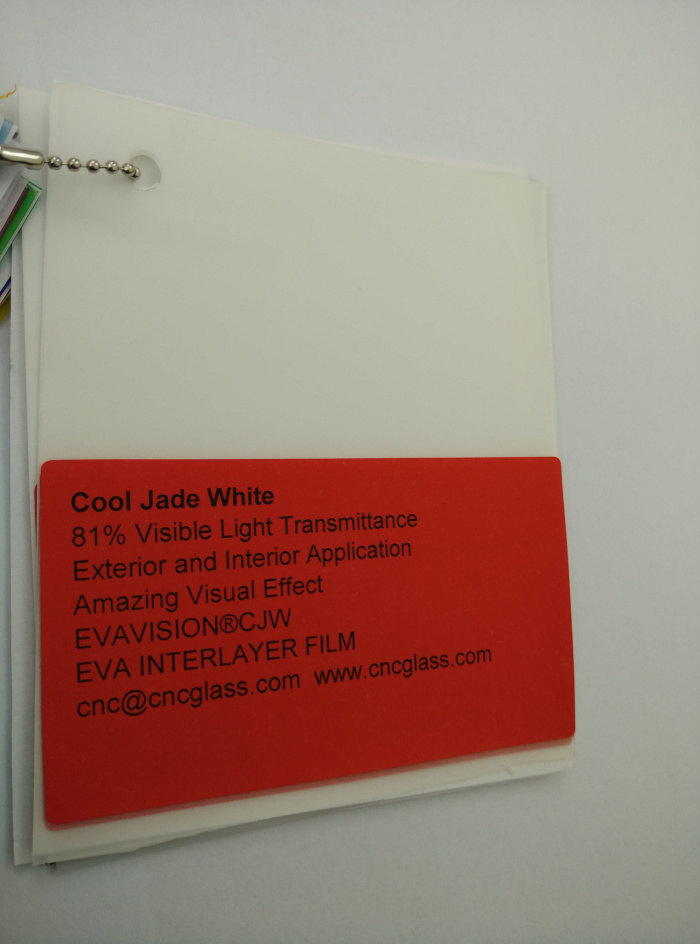

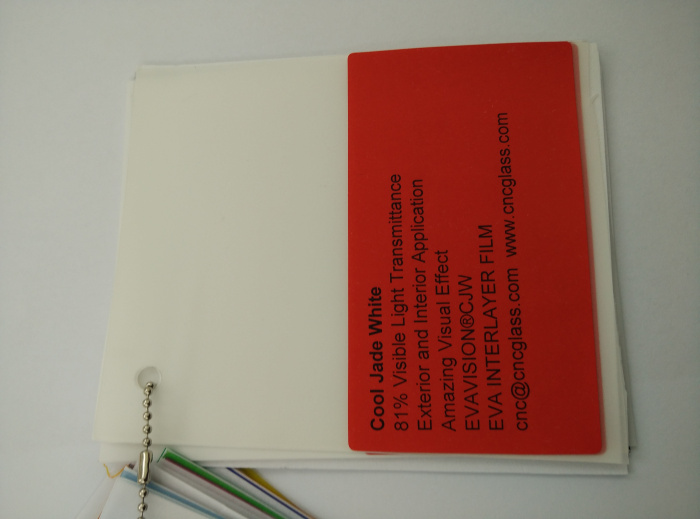

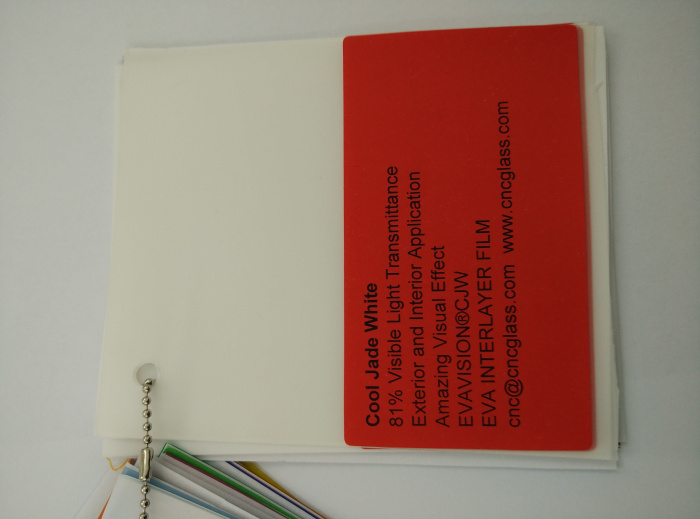

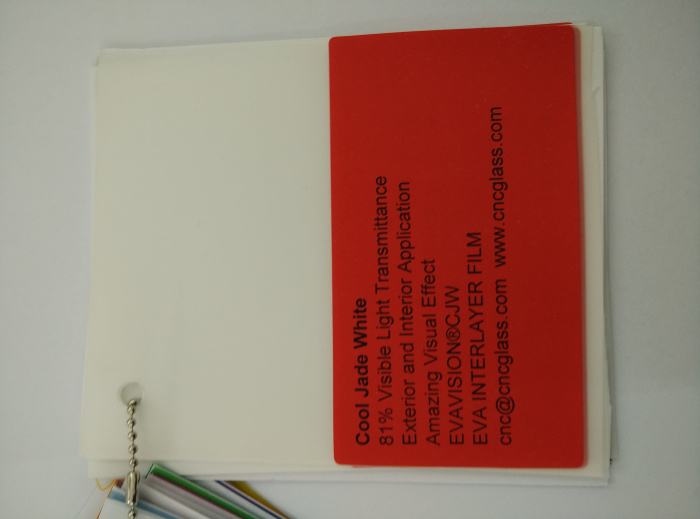

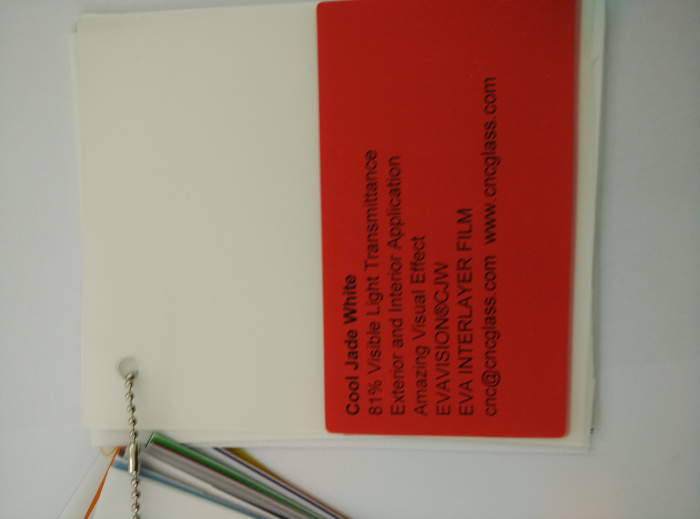

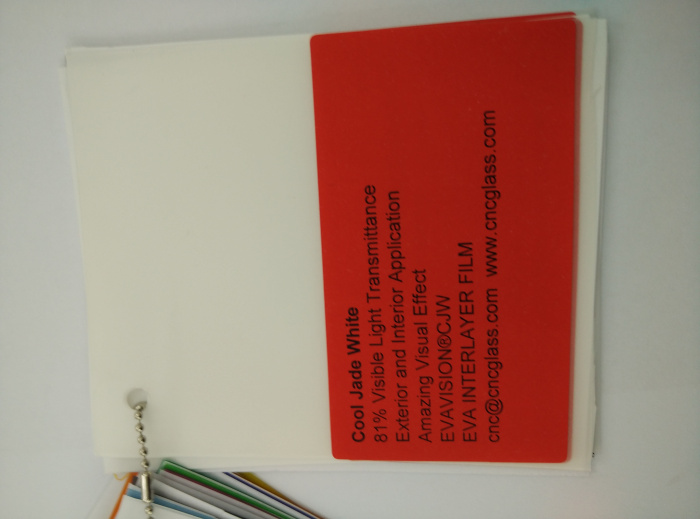

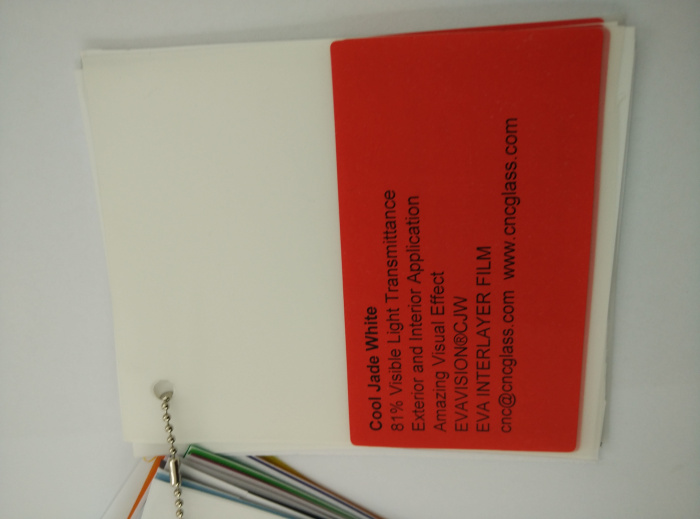

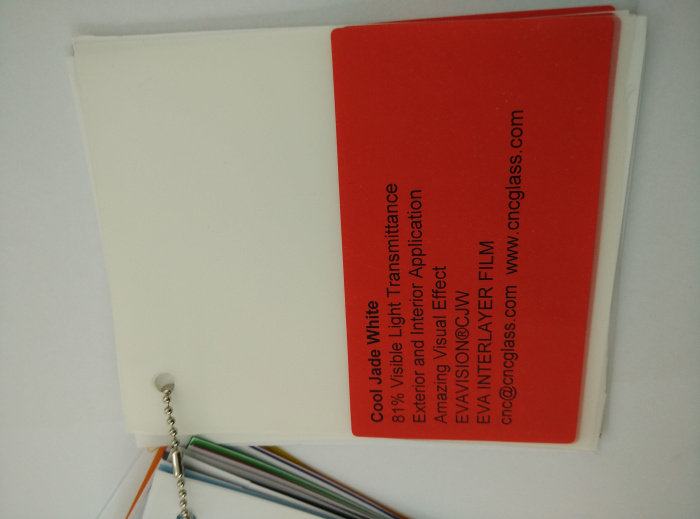

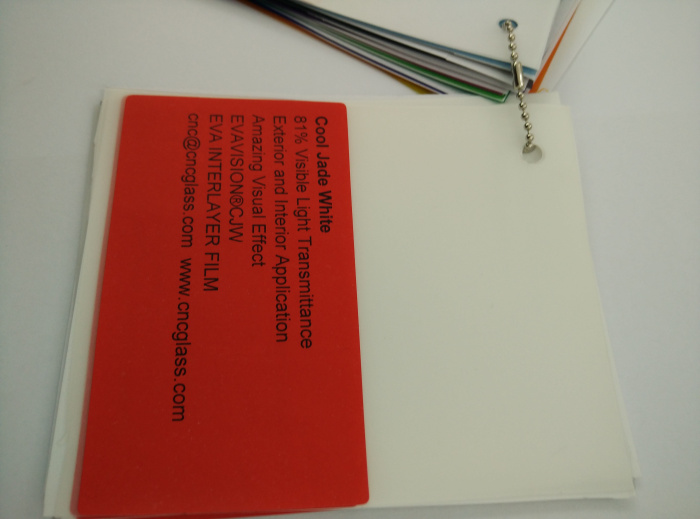

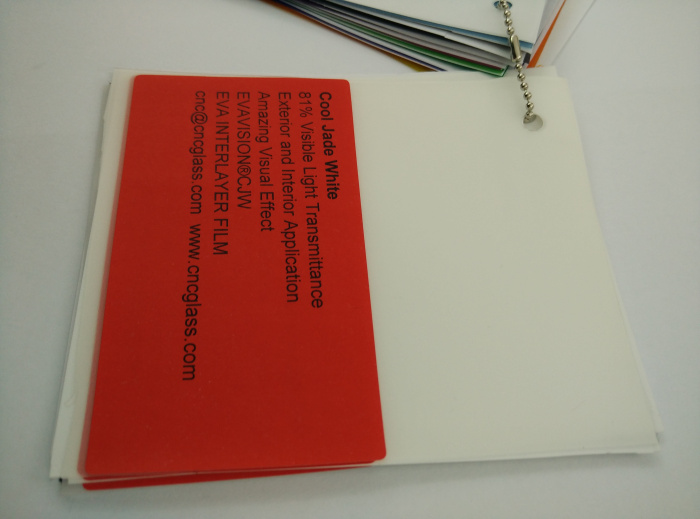

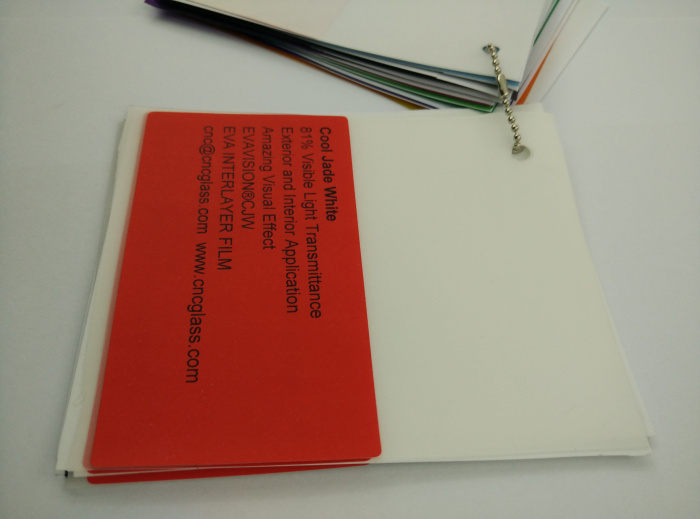

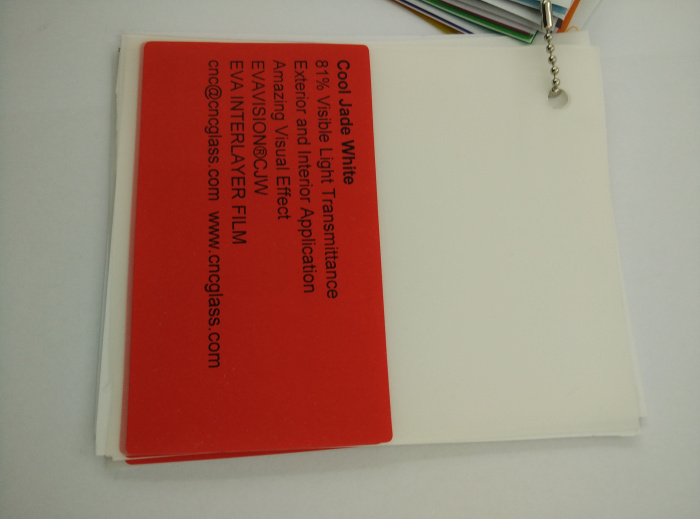

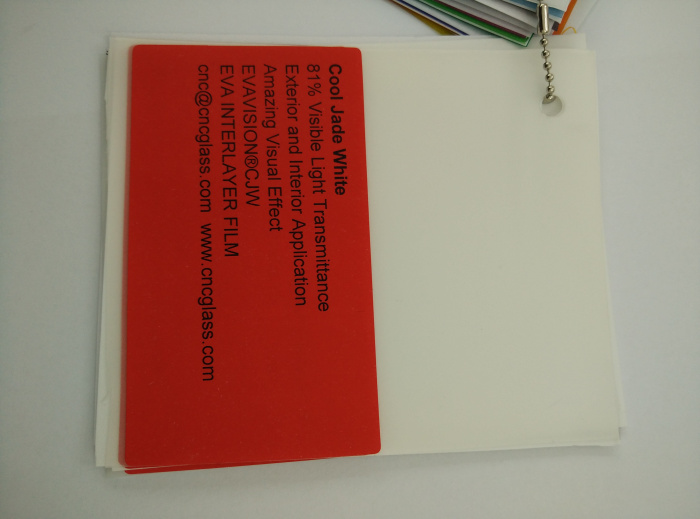

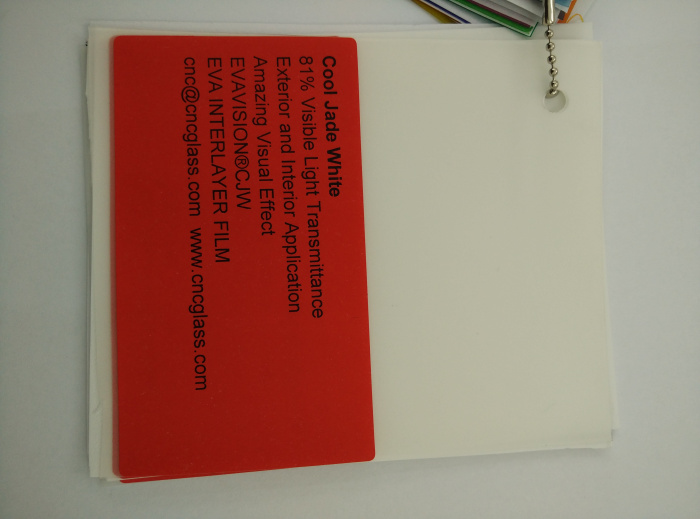

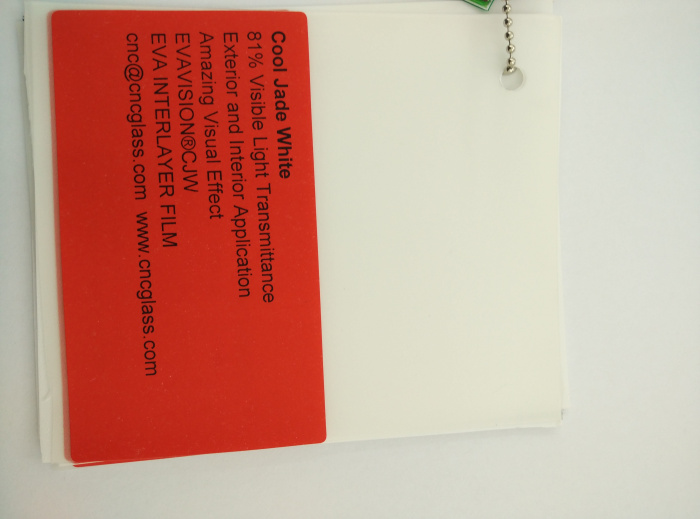

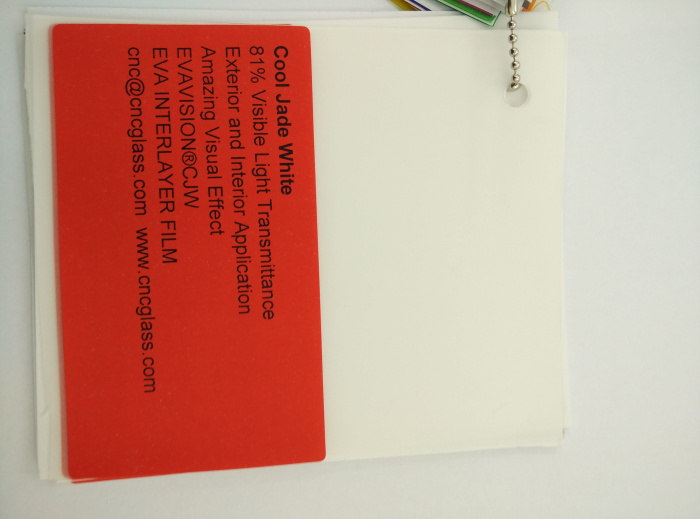

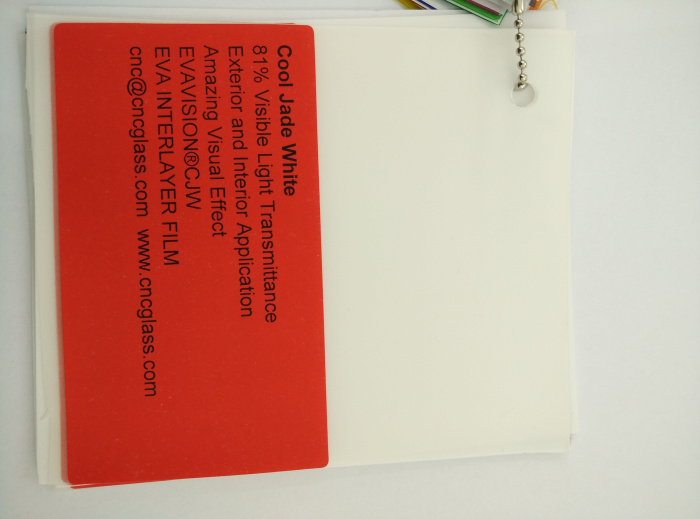

Cool Jade White Ethylene Vinyl Acetate Copolymer EVA interlayer film for laminated glass safety glazing

Silicone Vacuum Bag for EVALAM TEMPERED BEND lamination

![]()

[Silicone Vacuum Bag for EVA Glass Laminating Machine&Autoclave]

The combination of the silicone bag:

Upper Silicone Sheet

Down Silicone Sheet

Edge Gear

Silicone Tube

Description:

Product Purpose: used for glass vacuum laminating machines to make

safety laminated glass with EVA FILM INTERLAYER, or for making privacy glass, switchable glass with PDLC FILM and EVA FILM

Product features: heat-resistant, aging-resistance , anti-corrosive,environment-friendly, Long-use life, good resistance

Product specification:

1) common thickness: 3mm

2) maximum width:3800mm with no joint

3) any length

4) common color: transparent,red, and any color available

5)Customization is available as customers require

Notes When Using the Silicone Vacuum Bag

Please edging the glass before laminating, which can prohibit the sharp glass edges of the glass cut the silicone bag.

Use tape to seal the pre-laminated glass to reduce the EVA leaking from the laminated glass.

Use some papers/fabric to cover the silicone bag to separate the EVA from the silicone bag

Put some wires net on the vacuum hole to help vacuuming.

When not laminating , put the silicone bag out of the hot oven.

Classification of Silicone Blankets Based on Applications

(1-) for Safety Glass Laminating Vacuuming Oven

Thickness: 2mm / 3mm;

Color: Transparent, Blue

(2-) for Solar Cell Panel Laminators

Thickness: 3mm, 4mm, 5mm

(3-) for Wooden Door & Window Hot Press Machine

Thickness: 1mm, 1.5mm, 2mm

Procedure of Ordering:

(1)Be ware of the kind of silicone you need: for EVA glass lamination or for solar encapsulation.

(2)If you need silicone vacuum bag for EVA glass lamination, please offer the internal size and external size of the silicone bag.

(3)If you need silicone rubber sheet for solar encapsulation, please offer the thickness, width, length.

[Ethylene Vinyl Acetate EVA Interlayer Film for Laminated Glass]

EVA Film

EVA stands for Ethylene Vinyl Acetate Copolymer, a copolymer resin used in the production of laminated glass as the interlayer film sandwiched between two pieces of glass, like PVB Interlayer Film, and SGP Interlayer Film. The main function of the interlayer is to stick the two piece of glass together, in order to make the sandwiched glass safer and more secure.

EVA Film performs excellent in bonding strength, heat resistance, cold resistance, humidity resistance and tensile strength in laminated glass. It has been partly taking the places of PVB film in laminated safety glass, laminated art glass, and laminated color glass.

EVA film is not adhesive at room temperature. After heating, it melts and has cross-link reaction. In the production of laminated glass with EVA interlayer film, no autoclave, roller press, air bag, or vacuum rubber ring is required. As EVA interlayer Film can be processed under normal climatic conditions, no clean room with climatic control is required in PVB lamination. And the laminating machine line of laminated glass with EVA Film is less cost and easier to install. All laminating processing will be finished and completed in one vacuum laminator. EVA Film for laminated glass has excellent transparency, outstanding adhesion and aging-resistance (more than 15 years), can be used for architectural glass, decorative glass with fabric, privacy glass, auto glass etc.

Advantages of EVA film :

– High tensile strength

– Excellent transparency

– Outstanding adhesion

– UV protection

– High impact resistance

– Good temperature withstanding

– Water proof

– Humidity durable

– Long-term reliable (long-term aging resistance)

– Sound barrier

Names of EVA FILM for Laminated Glass

Some will call EVA Film in different name:

-laminated glass eva interlayer

-ethylene vinyl acetate film

-solar eva film

-glass lamination film

-glass laminating film

-laminating film rolls

-lamination film

-safety glass film

-tempered glass film

-security glass film

-glass eva film

-laminate film

-security laminate film

-decorative glass film

-stained glass film

[Introduction of EVA Interlayer Vacuum Bag Laminating Glass Machine]

EVA Vacuum Glass Laminating Machine is a equipment specially designed for manufacturing laminated safety and decoration glass with Ethylene-vinyl acetate EVA Interlayer Film (some kind of the one-step glass laminating machine can also processing Polyvinyl Butyral PVB Interlayer Film).

The EVA Vacuum Glass Laminating Machine uses the silicone vacuum bag to make the pre-laminated glass is heating in the vacuum condition to guarantee that final laminated glass don’t have bubbles.

It’s also possible to laminate EVA Interlayer Film with silk, paper, calligraphy and painting, ultraviolet radiation unilateralism film, light adjusted film and so on. All kinds of art glass, decorated glass, privacy glass, safety glass and solar panel can be processed in the EVA Vacuum Glass Laminating Machine.

Compared to autoclave producing line for Polyvinyl Butyral PVB Interlayer Film, the EVA Vacuum Glass Laminating Machine is much easier to operate and less cost to build., and more flexible and convenient for the designer.

(Notes: the knowledge here is a general guide, there is no guarantee that they are all correct or suits your laminating machine. )

All rights reserved by

UCOLIN GLASS SOLUTIONS

SILICONE VACUUM BAG FOR EVA LAMINATING MACHINE

[email protected]

www.ucolin.com

![]()

High Temperature Spray Coating Adhesive PET Green Tape

High Temperature Spray Coating Adhesive PET Green Tape

High Temperature Spray Coating Adhesive PET Green Tape

1)-Excellent tensile strength and welding strength: The GREEN PET TAPE FILM has been used for many heavy packages.

2)-Excellent tension maintenance. The GREEN PET TAPE FILM can maintain tensile strength for long time stretch with minimized strap slacking, at the same time ensuring excellent shock resistance, making GREEN PET TAPE FILM ideal for long-distance, long-period transportation.

3)-Excellent rusty and chemical resistance: Allowing direct strapping with The GREEN PET TAPE FILM without products damage or rusty.

4)-Ultra weather resistance: The GREEN PET TAPE FILM stays stabile under temperature of -50°C ~100°C, which ensures GREEN PET TAPE FILM is widely applied under any conditions.

980mm*66M/roll

600mm*66M/roll

25mm*66M/roll

30mm*66M/roll

40mm*66M/roll

50mm*66M/roll

STONE-EVA LAMINATED GLASS INSERTS

CNC EVA Film Super Clear External Type for Safety Laminated Glass

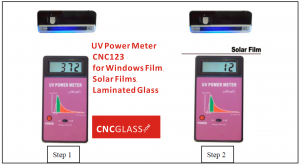

UV Power Meter CNC123 for Windows Film, Solar Films, Laminated Glass

UV Power Meter CNC123 for Windows Film, Solar Films, Laminated Glass

General Description

UV Power Meter CNC123 is a wide range spectral wavelength power meter. It can be used for

measuring the optical power density of UV light. It is used for

-Evaluating heat-insulating property of the tint of windows, solar films, glass and other transparent materials ;

-Measuring the power of ultraviolet radiation(260nm~380nm), gives visual and reliable

result ;

-UV sterilization and curing;

-General laboratory use;

Parameter

1-Accuracy : ±(4 %FS + 2digit) FS:Full scale

2-Infrared peak response wavelength is 365nm, range (260nm-380nm)

3-Scale: ×1 (0-1999 μW/cm2); ×10(2000 -19990 μW/cm2,displayed value×10)

4-Size: 125mm*68mm*22mm(L*W*H)

5-Weigh: about 110g

6-9V alkaline battery,6F22

Operation

Measure the UV power of solar or UV lamp

1-Put the meter at a suitable distance, and direct the end-mounted sensor to UV source, press the POWER key to switch on, select the suitable range for the measurement, the value will display.

2-Measure the UV rejection of solar control film, glass etc. it will take measuring in 2 steps.

Measuring the UV rejection of a solar film

1-Measuring the power of UV source UV1 W

2- Put the solar film in near front of the meter, measuring the transmitting power UV2 W ,

Then UV rejection = UV2 UV1 100%-W /W

In the example, UV rejection = UV2 UV1 100%-W /W =100%-12/372 = 96.77%

Tips

1-Measuring the UV rejection, Power meter should keep in the same position;

2- Choose the suitable measure range;

3-Turn off the power when not in use;

4-When change the battery, open the rear cover, use a new 6F22 alkaline battery;

5-Keep away from corrosive material, high temperature and humidity environment.

All rights reserved by CNC GLASS INTERLAYER TECH:

Product 1]CNC EVA INERLAYER FOR ARCHITECTURAL LAMINATED GLASS

Product 2]CNC PDLC SMART FILM FOR PRIVACY SWITCHABLE GLASS

Product 3]CNC PVB INTERLAYER FOR AUTOMOTIVE WINDSHIELD GLASS

WWW.CNCGLASS.COM

UV Power Meter CNC123 for Windows Film, Solar Films, Laminated Glass

Implications of EVA Film Laminated Glass

Implications of EVA Film Laminated Glass

Implications of EVA Film Laminated Glass

By Peter Lin

Outdoor Super-Transparent EVA Film for Architectural Safety Laminated Glass

Implied in:

Glass Railing, Curtain Wall, Canopy, Glass Doors, Shopping Malls Laminated Glass, Bullet-proof Glass, Glass Staircase.

Indoor Super-Transparent EVA Film for Decorative Laminated Glass

Compared to ordinary transparent EVA FILM, the indoor super-transparent EVA Films are better at transparence which can show a higher top great artistic sense. I will talk about this more in detail in next post.

Color-Transparent EVA FILM for Indoor Decorative Laminated Glass

Mainly implied in:

KTV Bar, Cafe, Restaurant, Business Hall, Dance Studio, Home Improvement, Sales Department , Mall, Villa, Floor, Stairs, etc.

Color-Translucent EVA FILM for Indoor Decorative Laminated Glass

Mainly implied in:

KTV Bar, Disco, Restaurant, Sales Department, Operating Room, Coffee Shop, Table, Villa , Studi, Bathroom, Floor Laminated Glass, Stair Laminated Glass, Mall, etc.

All rights reserved by CNC GLASS INTERLAYER TECH:

Product 1]CNC EVA FILM INERLAYER FOR ARCHITECTURAL LAMINATED GLASS

Product 2]CNC PDLC SMART GLASS FILM FOR PRIVACY SWITCHABLE GLASS

Product 3]CNC PVB FILM INTERLAYER FOR AUTOMOTIVE WINDSHIELD GLASS

Hot Knife, Heat Cutter, Foam Cutter, Fabric Cutter, EVA Thermal Cutter

Hot Knife, Heat Cutter, Foam Cutter, Fabric Cutter, EVA Thermal Cutter

Hot Knife Heat Cutter Foam Cutter Fabric Cutter

UC-8-0

Application:

Hand operated tool to cut small quantities. Suitable to cut braid rubber.rubber sheet or stick, natural or natural or synthetical rubber. Heat up time of blades approx 5-7 seconds.Heat may be controlled by switching tool on and off.Fitted with different blades, it can be used to cut thin fabric too.

Cut Synthetic Fabric, Sail Cloth, Webbing, EVA film, PVB film, Ropes & Cords

Technical Data:

Supply voltage: 230V/50Hz(110V/60Hz)

Power input: 120W

Intermittent operation: 1/4 min

Weight: 1.0Kg

Power cord length: 3.0m

Basic Kit:

Handle, 100mm blade, Tool box,cleaning brush and spanner.

Hot Knife polystyrene foam cutter is a great all around hot knife foam cutter. Excellent for contractors, hobbyist, shipping departments and anywhere else one needs to cut expanded or extruded polystyrene foam. Our customers prefer cutting foam with the Hot Knife because of how clean it cuts and leaves no dust compared to cutting with a saw.

Electric heating cutter available in several blades to remove the remains of EVA film of laminated glass

Introduction:

The Hot Knife(Heat Cutter, Foam Cutter, Fabric Cutter, EVA Thermal Cutter) is a professional-grade hot cutting tool for EVA Film&Fabrics. The Hot Knife(Heat Cutter, Foam Cutter, Fabric Cutter, EVA Thermal Cutter) heats up in seconds and gives the operator temperature control. Never before has working with EVA Film&Fabrics been this easy, inexpensive and free of mess.

Recommended Use:

Terylene EVA Film&Fabrics, EVA Film of laminated glass, PVB Film of laminated glass, SGP Film of laminated glass, Fiberglass Fabrics and Polyester Fabrics can be easily cut with Hot Knife(Heat Cutter, Foam Cutter, Fabric Cutter, EVA Thermal Cutter) .

Blade Installation:

NOTE: Always unplug cord of the Hot Knife(Heat Cutter, Foam Cutter, Fabric Cutter, EVA Thermal Cutter) before installing or removing the blades. Allow sufficient cooling time for blades, blade holders and metal thumb wheels before handing.

Caution 1: The Hot Knife(Heat Cutter, Foam Cutter, Fabric Cutter, EVA Thermal Cutter) blade have a sharpened razor edge, for the cleanest cut always cut in the direction on the sharpened edge.

Blades:

1-Loosen the screws on the blade holders with the wrench.

2-Slide the blade under the square pressure plate until snug

3-Securely tighten screws to assure the proper electrical connection. Do not over-tighten.

4-Once the blade is firmly in place, plug in the Hot Knife(Heat Cutter, Foam Cutter, Fabric Cutter, EVA Thermal Cutter) Unit into a standard power supply.

5-The temperature control knob has 16 click setting that correspond to the graduated ridges on the surface. The smaller the ridge the lower the power setting.

Caution 2: Excessive power output and heat generation may cause the blade holders to overheat resulting in damage to the unit. Use only the power output for proper cutting. The blade does not need to be red hot to move through foamed plastics.

Operation:

Put your temperature control knob at midrange setting, place the blade against the edge of the foam and depress trigger. Optimum cutting should be virtually smoke free.

NOTE: For the best results, practice on scrap pieces of EVA Film&Fabrics .

When cutting foam it is best to keep the temperature and speed consistent. If smoke develops during the cut, you are cutting too slow or the blade is to hot which could result in an over-sized, uneven cut. This can be remedied by lowering the temperature and intermittently releasing the trigger during your cut. As the cutting resistance increases, depress the trigger again. The Hot Knife(Heat Cutter, Foam Cutter, Fabric Cutter, EVA Thermal Cutter) will reach the set temperature within seconds. You can accomplish your cut with minimal smoke using this process. Cutting in this manner will also prolong the life of the knife.

Releasing the trigger approximately one or tow inches prior to the completion of the cut will help keep the blade clean and free from buildup

Caution 3:

Always operate the Hot Knife(Heat Cutter, Foam Cutter, Fabric Cutter, EVA Thermal Cutter) in well ventilated space

Never burn off excess residue on the hot knife blade. The blades will overheat, warping the blade and potentially overheating the Hot Knife(Heat Cutter, Foam Cutter, Fabric Cutter, EVA Thermal Cutter) .

Only operate Hot Knife(Heat Cutter, Foam Cutter, Fabric Cutter, EVA Thermal Cutter) when it is in contact with the insulation board.

Keep hot blades away from skin, clothing and other flammable materials.

Allow blades to cool before handling. A hot blade may cause injury or burns to exposed surfaces.

Maintenance:

Constant use of the Hot Knife(Heat Cutter, Foam Cutter, Fabric Cutter, EVA Thermal Cutter) may result in some material build up on blades and the brass holders. This excess material interferes with the proper electrical and impairs the performance of the blades. The brass blade holders and blades can be thoroughly cleaned with a wire brush.

Customer Review:

Loved it very much! I used the hot knife for cutting 4’x8′ sheets of styrofoam insulation (1″ thick) to make mural backdrops. Great product! I had so much fun cutting a skyline to make a backdrop. Since then, I’ve had several people ask to borrow it. If you’ve ever tried to cut styrofoam with a saw or regular knife you know what a mess it makes, but this seals the edges as it cuts and keeps the “little micro-beads” of styrofoam under control.

All rights reserved by UCOLIN TECH:

www.ucolin.com

[email protected]

GLASS BUILDINGS

China Glass Expo Glass Files Sharing

Sharing is Great!

Sharing Keeps Glass Great!

Shared by:

Silicone vacuum bag for EVA glass laminating furnace, EVA oven, EVA machine

Read Silicone Bag For Laminated Smart Glass With Eva Interlayer In …

http://free.yudu.com/item/details/549657/Silicone-Bag-for-Laminated-Smart-Gla…

Read Silicone Bag For Laminated Smart Glass With Eva Interlayer In …